Innovative engineering, responsive support, and tactile solutions converge to extend product life and win customer trust.

| Company | Avid Product Development |

| Location | Loveland, Colorado |

| Product | Limit Switch |

| Industry | Industrial Equipment |

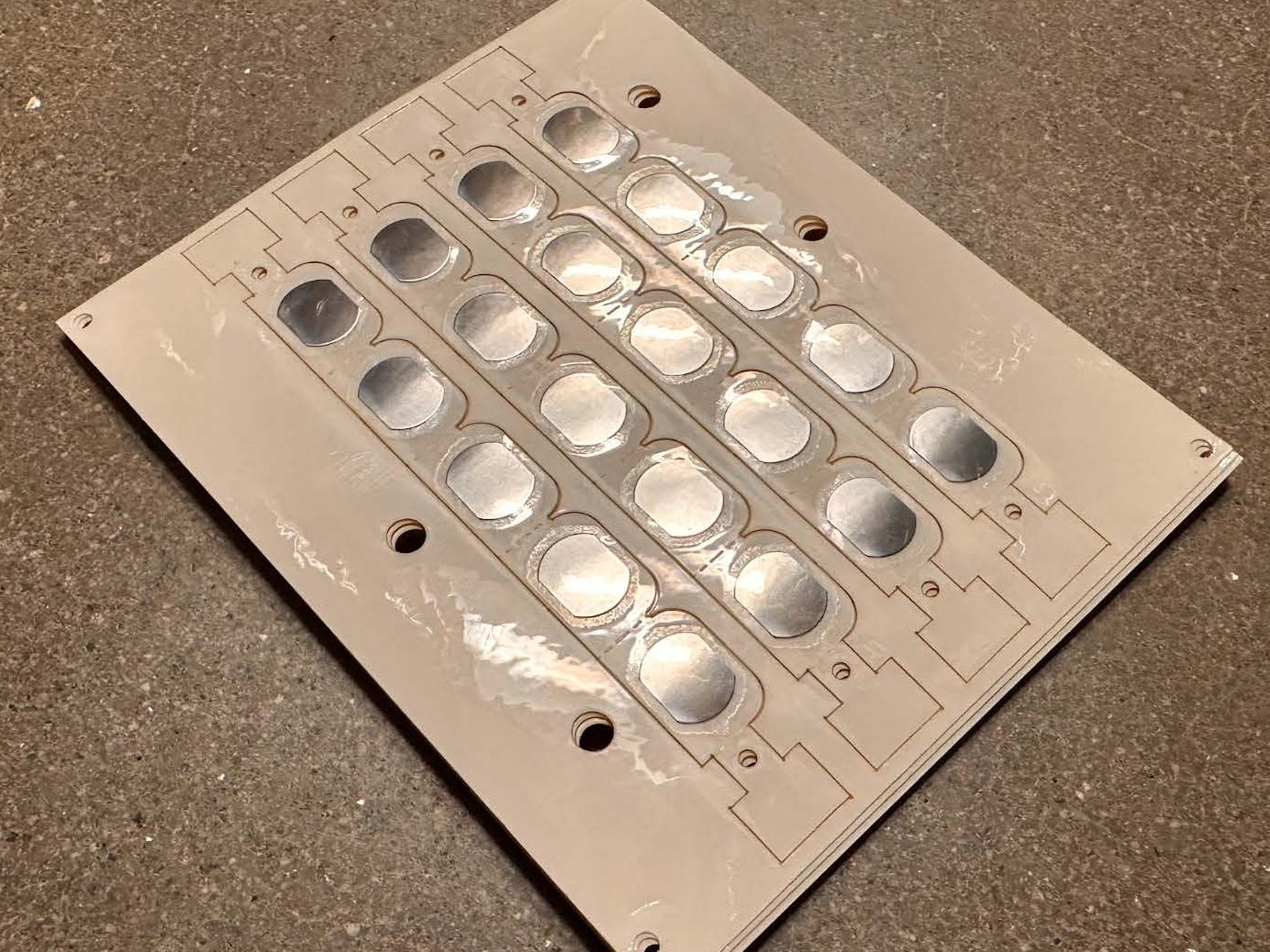

| Materials/Services Used | RK50040, Custom PNP |

Designing for Durability

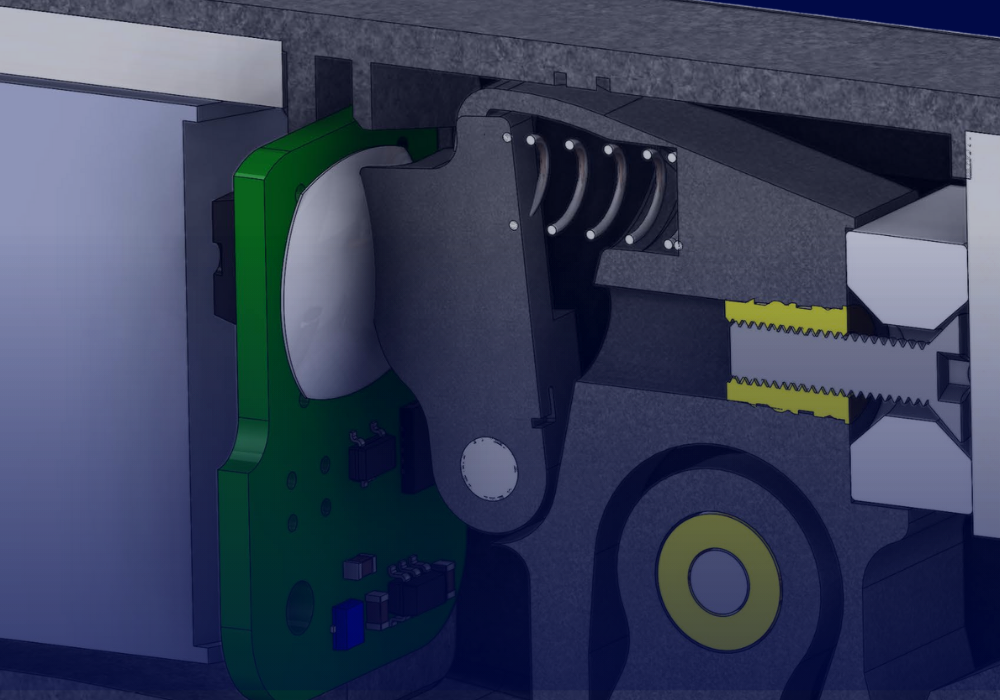

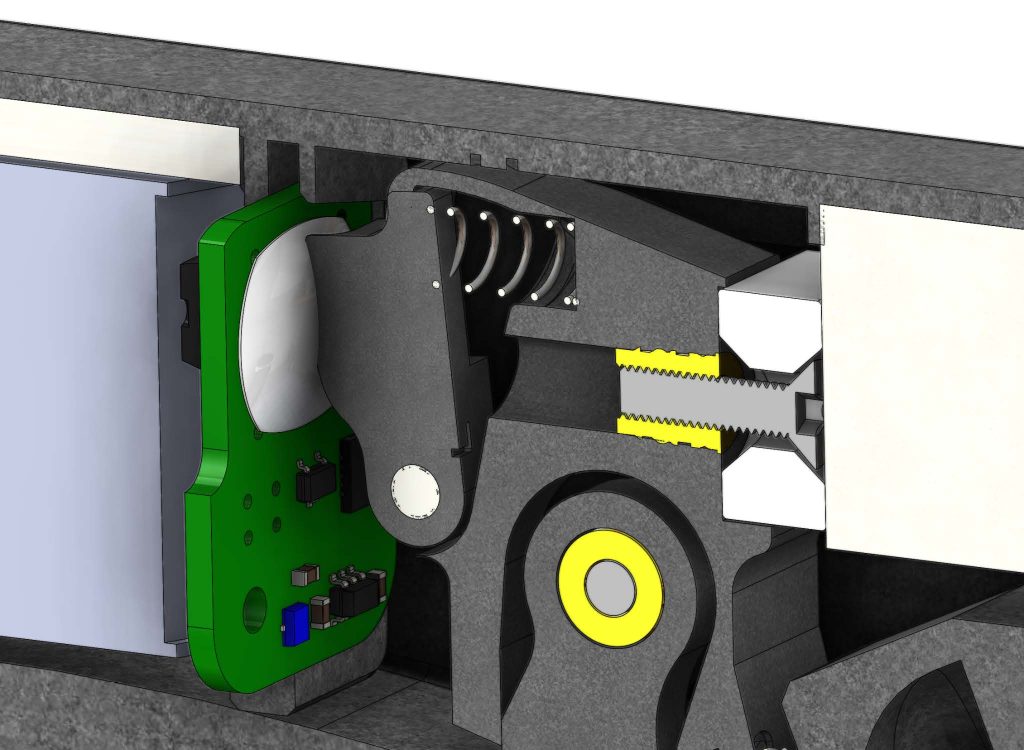

When a long-time client of Avid Product Development came to them with a serious reliability issue, the stakes were high. The client’s product, built with a standard limit switch, was failing at an alarming rate. Each unit was expected to last over a million cycles, but the switches gave out far too early. It wasn’t just a technical hiccup; it was a critical performance bottleneck that jeopardized the customer’s confidence.

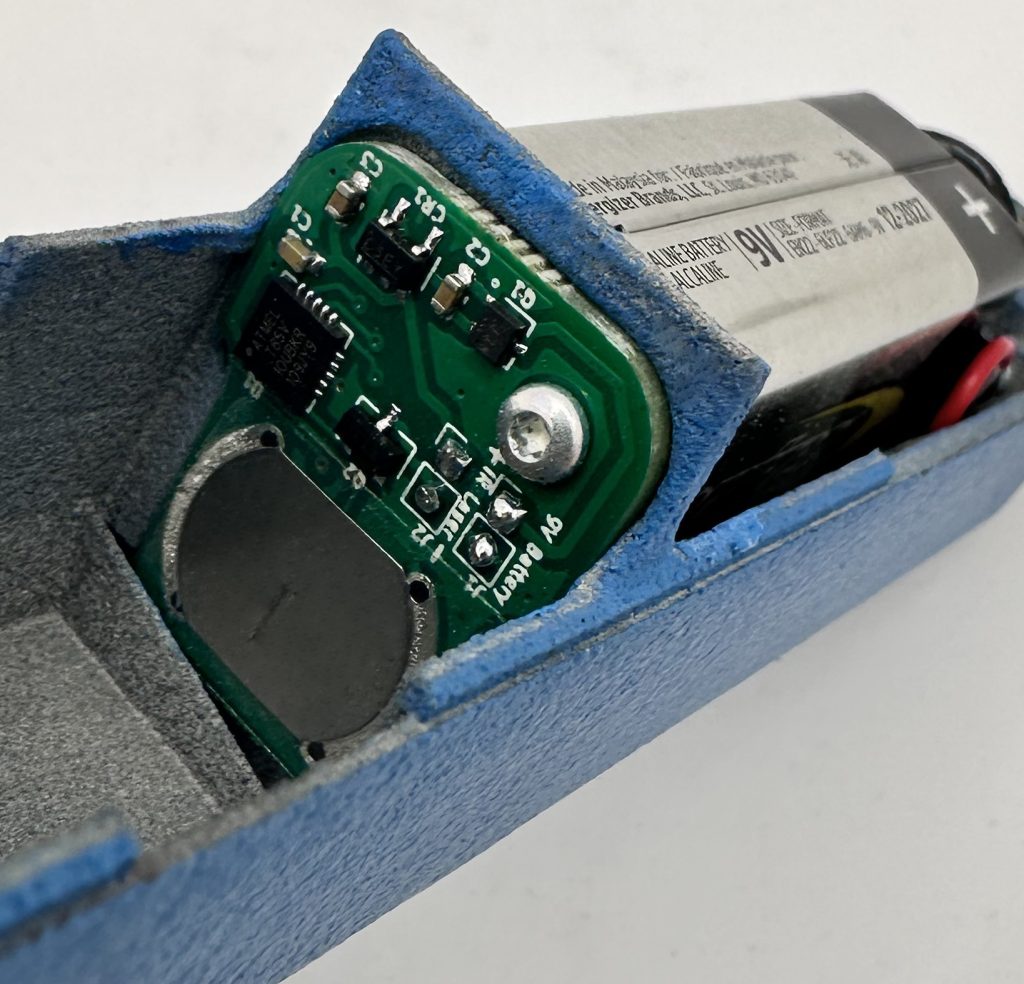

For Avid—a Colorado-based product design, engineering, and additive manufacturing company trusted by clients ranging from solo innovators to Fortune 500 leaders—this was more than just another engineering challenge. It was a chance to turn a pain point into a long-term partnership.

Rethinking the Switch

Dawson Swan, Avid’s Engineering Manager, knew the solution needed to be rock-solid. “Our client’s failure rate was nearly 100%, and the limit switch was one of the biggest contributors,” he recalls. The team needed a component that was small, reliable, and built to withstand a million-plus actuations.

Snaptron, also based in Colorado, came to mind immediately. Known for their tactile dome switches and engineering support, Snaptron had the reputation and proximity Avid needed. “Snaptron was local and had a great reputation in the industry,” says Swan.

Engineering a New Standard

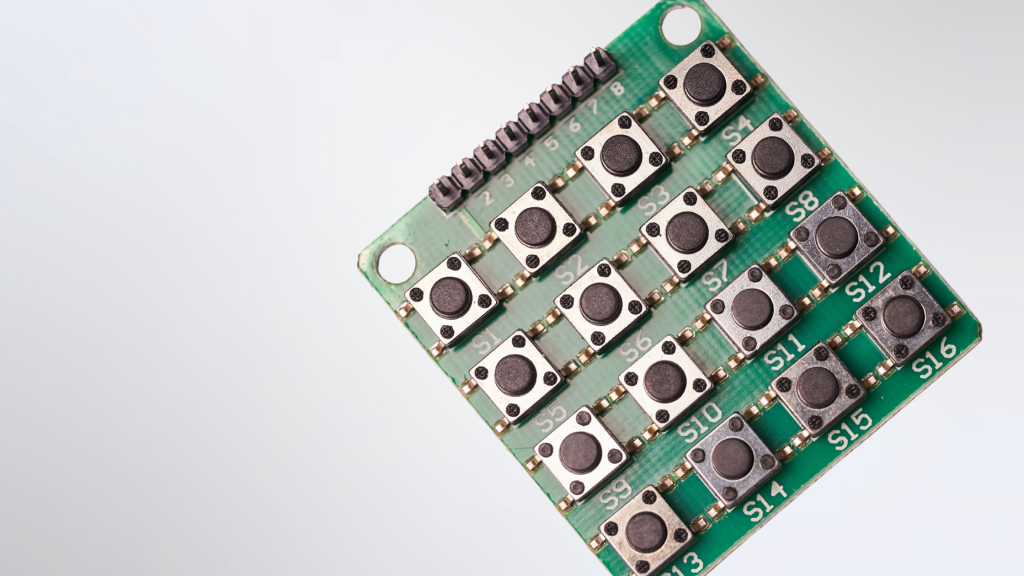

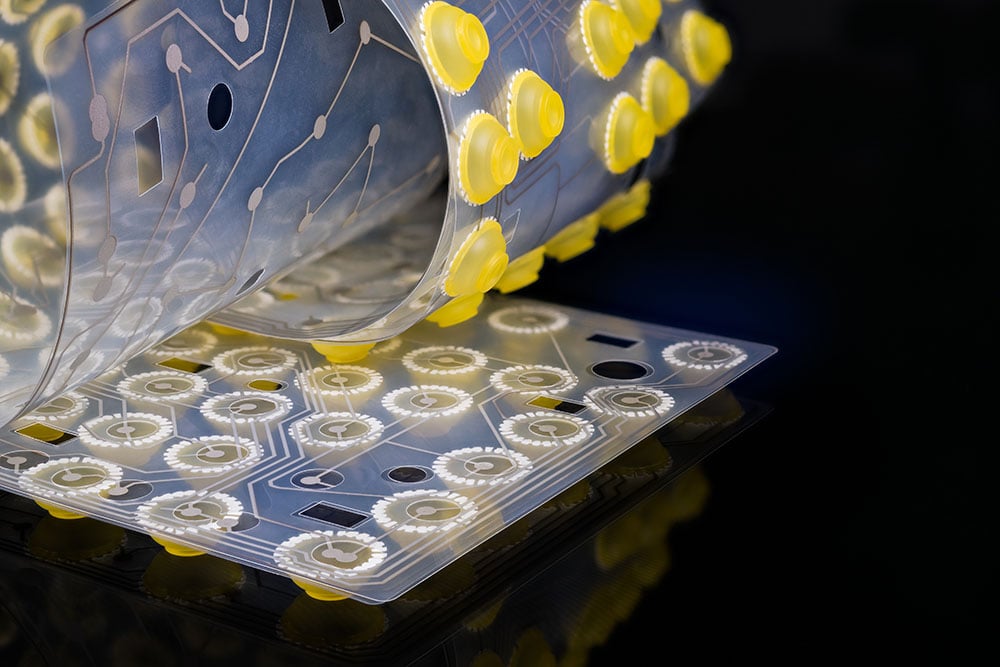

Snaptron supplied Avid with a variety of dome samples, allowing the team to dial in exactly the right tactile feel and performance characteristics. The Snaptron team also offered support for optimizing the switch assembly, ensuring a robust design from the inside out.

“There were no major roadblocks during development,” says Swan. “The sample kits were excellent, and the team helped us find the right assembly method. It was smooth and led to us continuing to use Snaptron seven years later.”

As the product evolved, Avid changed the dome panel configurations several times—and Snaptron supported every iteration. That flexibility helped Avid deliver a solution their client could finally trust.

The Results: A 100% Problem Turns into a 1% Issue

The impact was immediate. The redesigned product, now featuring a custom oval dome switch, experienced a significant reduction in its failure rate. Dropping returns due to switch failure from nearly 100% to 0%. For Avid’s client, it wasn’t just a fix—it was a game changer that transformed the way they approached future development. The results underscored the value of high-performance components in demanding applications where longevity and durability are critical.

For Avid, the project’s success transformed a one-time challenge into a long-term customer relationship. “The success of that product helped us win over a loyal customer who continues to develop products with us today,” says Swan.

Looking Ahead

Avid continues to integrate Snaptron switches wherever it makes sense. Whether for prototyping or low-volume production, the reliability and feel of the domes—combined with Snaptron’s support—have made them a go-to solution for precision engineering projects.

“We would absolutely recommend Snaptron,” Swan says. “They’ve been a great partner in helping us build better products.”