Tactile switches play a critical role in modern user interfaces, delivering essential physical feedback that enhances both precision and user experience. From medical devices to industrial controls and consumer electronics, tactile switches are engineered to provide a noticeable ‘bump’ during actuation, signaling to users that their input has been successfully registered. This article examines the mechanics, benefits, and various types of tactile switches, with a focus on selecting the ideal switch for your specific application.

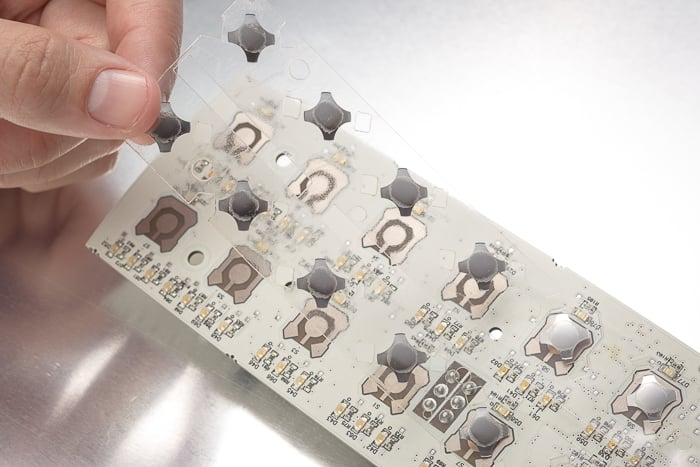

Metal dome switches on a white printed circuit board (PCB) and adhesive tape.

What Are Tactile Switches?

A tactile switch is a type of momentary switch that provides a physical response when actuated. Unlike linear switches, which provide no feedback, or clicky switches, which generate both tactile and audible responses, tactile switches strike a balance by delivering a perceptible ‘bump’ without excessive noise. This makes them ideal for applications where both confirmation and discretion are required.

How Do Tactile Switches Work?

Tactile switches typically consist of four main components:

- Contact Terminal: Conductive element that closes the electrical circuit when compressed.

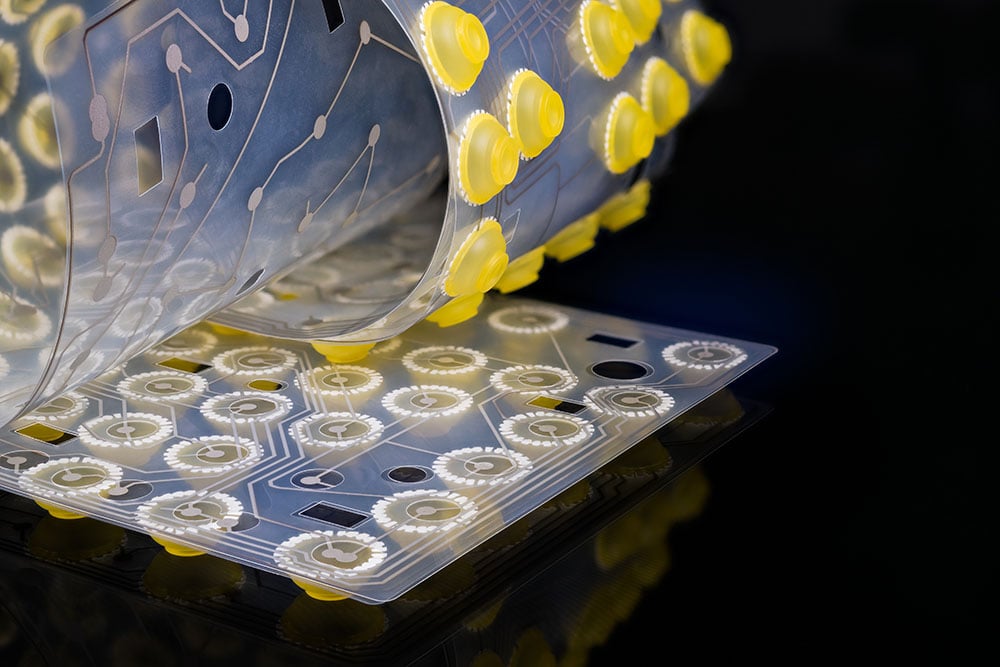

- Dome: A metal or polymer dome that collapses and springs back to provide tactile feedback.

- Plunger: Transfers user force to the dome, initiating actuation.

- Cover: Encloses the components and maintains mechanical integrity.

When pressed, the plunger pushes against the dome, deforming it and closing the circuit by bringing the contact terminal into engagement. Once pressure is released, the dome snaps back to its original shape, breaking the circuit. This simple mechanical action is highly repeatable and offers a tactile confirmation of actuation.

Tactile metal domes, in particular, are even more mechanically streamlined—eliminating components like plungers and covers entirely. Their compact design makes them ideal for ultra-low-profile applications where space and simplicity are critical.

Types of Tactile Switches

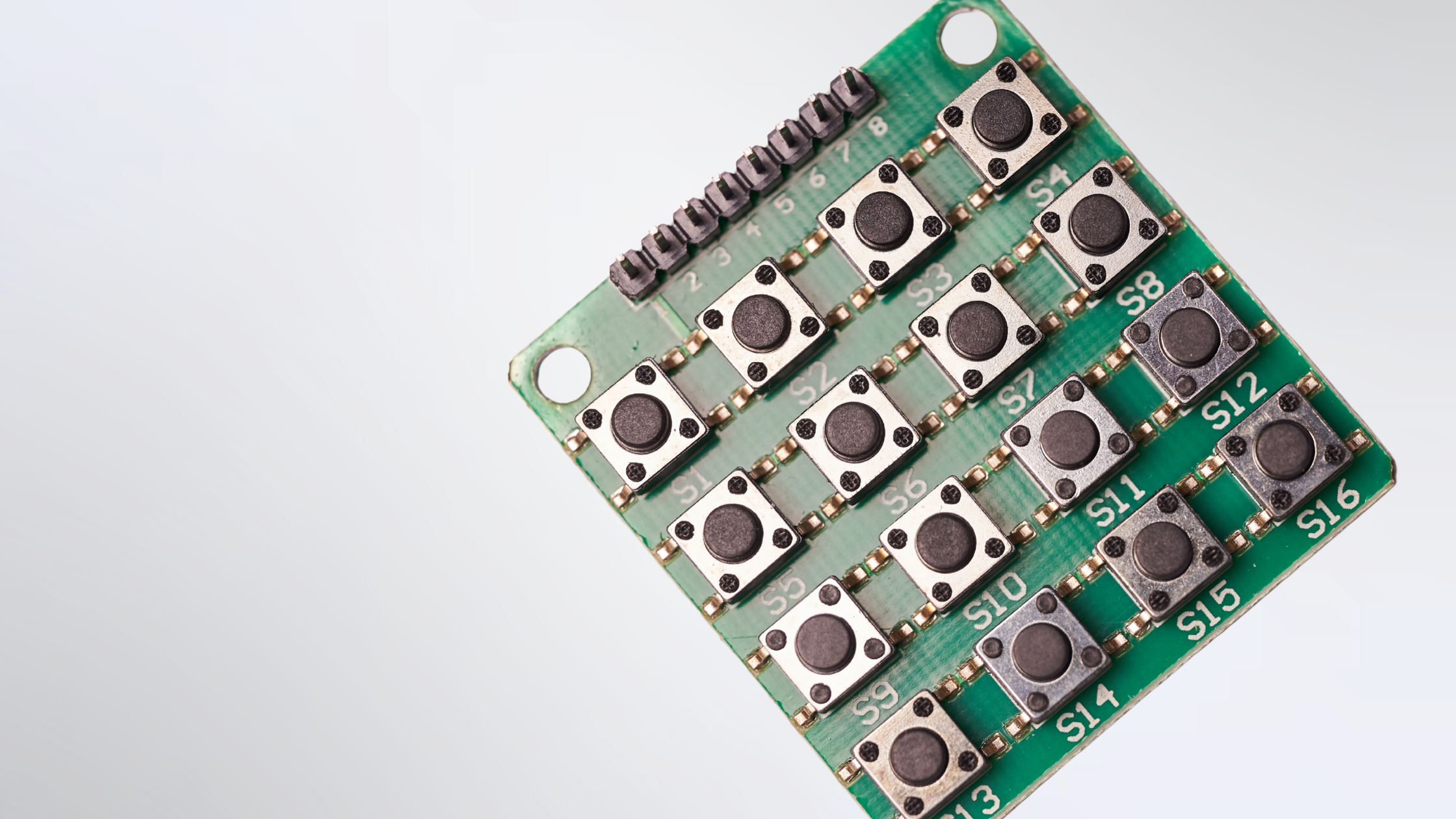

Tactile switches are available in a variety of form factors, each designed to meet specific application needs:

| Type | Description | Use Cases |

| Standard | Commonly used in general electronics. Medium profile. | Consumer electronics, control panels |

| Sealed | Protected against dust and moisture. | Medical devices, outdoor equipment |

| SMT (Surface-Mount) | Mounted directly onto PCB surface. Compact and efficient. | High-volume electronics, compact modules |

| Long Stroke | Greater travel distance, more tactile feedback. | Industrial equipment, automotive controls |

| Medium Stroke | Balanced travel and feedback. | Consumer interfaces, appliances |

| Hinge Lever | Activated by mechanical leverage. | Specialized machinery, automotive HVAC systems |

| Metal Domes | Low-profile, highly durable metal-based tactile elements. | Wearables, keypads, compact control systems |

Benefits of Tactile Switches

Tactile switches are chosen not only for their feel but also for their functional advantages:

- Intuitive User Experience: The tactile response reduces the need for visual confirmation, enabling confident operation—even in low-light or distraction-heavy environments.

- Versatility Across Industries: Found in automotive dashboards, surgical tools, consumer electronics, and industrial control systems.

- Enhanced Durability and Reliability: Rated for millions of cycles, tactile switches withstand repeated use without degradation in performance.

- Tangible Feedback: The physical ‘bump’ confirms actuation, ensuring that inputs are deliberate—crucial in safety-critical applications.

- Improved Accuracy and Control: Reduces unintended activations, which is essential for high-precision environments like medical equipment or heavy machinery.

- Reduced Fatigue During Extended Use: Many tactile switches actuate before full depression, minimizing repetitive strain.

- Noise Management: While not silent, tactile switches are quieter than clicky types, making them ideal for shared or noise-sensitive environments.

When Should You Choose a Tactile Switch?

Tactile switches are the ideal choice when precision, feedback, and control matter most. Specific use cases include:

- Safety-Critical Interfaces: In automotive, aerospace, and medical applications, tactile feedback helps prevent accidental presses and confirms critical actions.

- Precision Equipment: When working with navigation, diagnostics, or measurement tools, the tactile bump supports accurate, deliberate input.

- Shared or Quiet Workspaces: Offices, libraries, and hospitals benefit from the quieter operation of tactile switches over clicky alternatives.

- Extended-Use Interfaces: For control systems or devices requiring frequent operation, the low actuation effort and feedback reduce strain and improve ergonomics.

How to Choose the Right Tactile Switch

When selecting a tactile switch, engineers should evaluate the following technical specifications:

- Tactile Force: The amount of force (measured in grams) required to register actuation—typically ranges from 160gf to 700gf.

- Travel Distance:

- Actuation Distance: How far the switch travels before registering.

- Total Travel: Full range from top to bottom.

- Tactile Ratio: A measure of how distinct the bump feels during actuation, calculated by the ratio of tactile peak force to actuation force.

- Cycle Rating: Indicates durability—typically 1 million to over 5 million cycles depending on switch type.

- Contact Resistance: Electrical resistance at the point of contact; lower values ensure faster signal response and cleaner electrical connection.

- Mounting Type: Through-hole, surface-mount, or dome-integrated depending on PCB layout and assembly requirements.

- Environmental Ratings: IP ratings for dust and moisture resistance, especially important for medical, military, or outdoor use.

Snaptron’s tactile domes are engineered with precision, offering a wide range of tactile profiles, force ratings, and mounting options tailored for reliability, miniaturization, and user experience.

Snaptron’s Sapphire Switch Tester measures the force curve on a keyboard switch.

Conclusion

Tactile switches are critical components in applications requiring reliable, immediate feedback—without sacrificing size, noise, or durability. For engineers, their mechanical simplicity, longevity, and tactile clarity make them a superior choice compared to capacitive or linear alternatives, especially in safety-critical and space-constrained environments.

From ultra-thin wearables to high-use industrial panels, tactile switches provide the physical confirmation users need to operate with confidence. By understanding their construction, types, and key performance metrics, designers can select a switch that not only fits their technical requirements but also enhances the overall functionality and safety of the device.