When it comes to finding the right dome switch, designers must work around standard domes’ limitations or find a custom solution. So how do you know if metal dome switches are right for your application? Below are five of the most frequently asked questions on metal dome switches we get from engineers looking for switches for their products.

1. How are metal domes packaged?

There are several different packaging methods to choose from, depending on your application. Metal domes can be packaged in bulk (jars), in cartridges for use with the Dart™ Placement Pen or the SureShot™ automated dome placement machine, in pocketed reels for use with pick and place equipment, or on polyester-adhesive sheets (Standard Peel-N-Place arrays or Custom Peel-N-Place arrays).

2. Can metal dome switches be soldered to a circuit board?

Yes, certain dome styles, such as the S-Series, can be soldered to a circuit. Two solderable tabs on S-Series, also known as SMD domes, allow the dome to be soldered directly to a printed circuit board or flex circuit without impacting performance or tactile feel. When the domes are pushed, the feet move outward. If this movement is restricted, it can negatively affect the tactile response of the domes and, in some cases, cause irreparable damage to the domes or break the solder joint. Therefore, when not using solder domes, Snaptron does not recommend soldering.

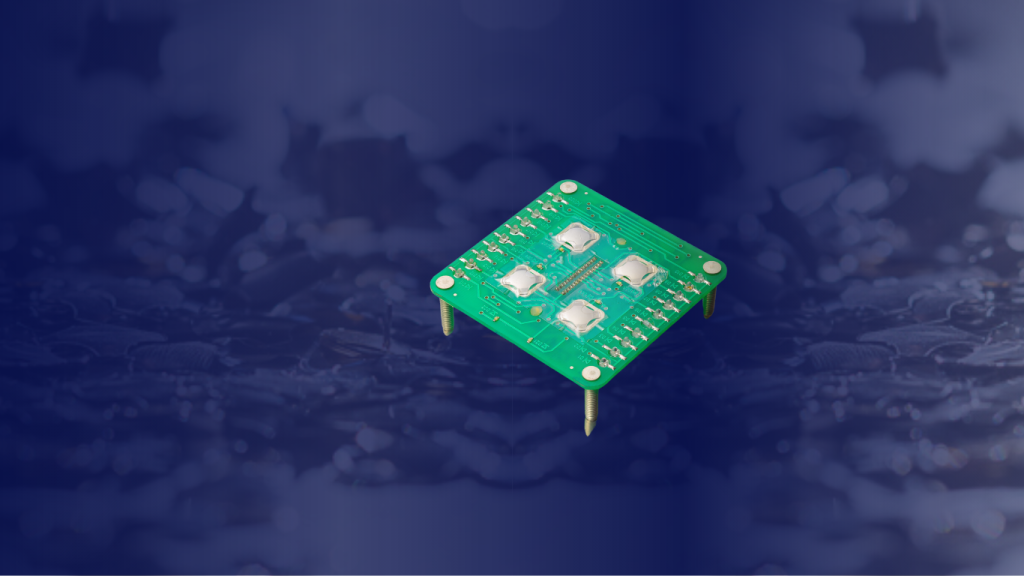

3. How do I secure the metal domes to my PCB, membrane, or flex circuit?

Metal dome switches are secured using pressure-sensitive adhesive tape or can be soldered down by hand or with an SMT machine in a solder reflow process, depending on the style of the dome. Several standard adhesive material options are available, as well as custom materials. See our Peel-N-Place Arrays for more information on placing the domes with tape.

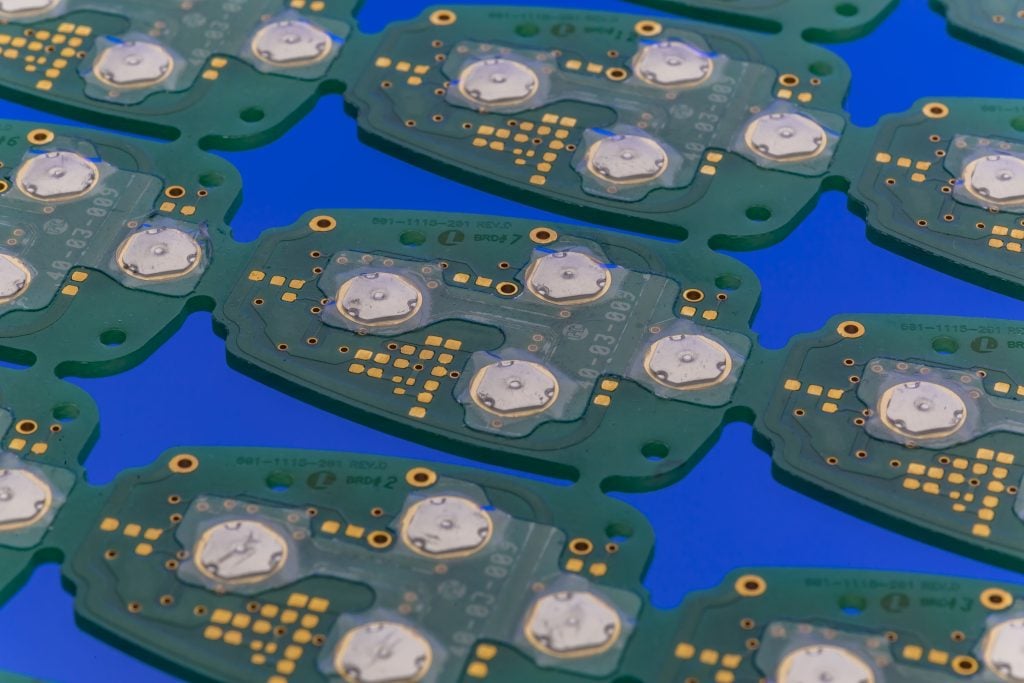

4. Can metal dome switches be assembled with standard pick-and-place equipment?

Yes, Snaptron offers pocketed reel packaging for use with automated placement equipment. Please contact us for more information regarding automated metal dome placement equipment.

5. Is there a recommended actuator for depressing the domes?

While there are several different sizes and shapes of actuators, we recommend you test the metal domes’ actuation force with a flat bottom plunger 20-25% of the dome size. Anything larger can crush the dome and reduce its designed force and travel. Anything smaller can create a dimple in the dome and limit its designed travel. Different types of actuators can affect the tactile feel of our switch. For example, silicone actuators provide a crisp tactile feel with dull acoustics. See our quality test procedures for more information on testing domes.

Have more questions about metal dome switches? Contact us today to learn if dome switches are right for your application.