Frequently Asked Questions About Tactile Domes

Whether you’re new to this technology or seeking more in-depth information, this page is here to answer all your questions. Tactile dome switches are widely used in various industries due to their reliability, responsiveness, and durability. These switches play a critical role in many devices, offering tactile feedback that enhances user interaction. Here, you’ll find detailed answers to common questions about their functionality, applications, benefits, and more.

Q. Do you have local distributors in our area?

A: While we ship our products worldwide directly from our Windsor, Colorado, USA facility via your preferred shipping method, we also partner with DigiKey to distribute a select range of our products. Contact us to set up an account.

Q. How can I purchase metal domes from Snaptron?

A. All purchases are made directly from Snaptron, which offers various ways to purchase metal domes. You can set up NET 30 terms, where we invoice you after purchase. Snaptron also accepts major credit cards or payments in advance.

Q. How are the domes packaged?

A. Depending on your specific application, you can choose from several different packaging methods. The domes can be packaged in bulk (jars), in cartridges for use with the Dart™ placement pen and the SureShot™ automated dome placement machine, in tape and reels for use with pick-and-place equipment, and on polyester-adhesive sheets (Standard Peel-N-Place arrays or Custom Peel-N-Place arrays).

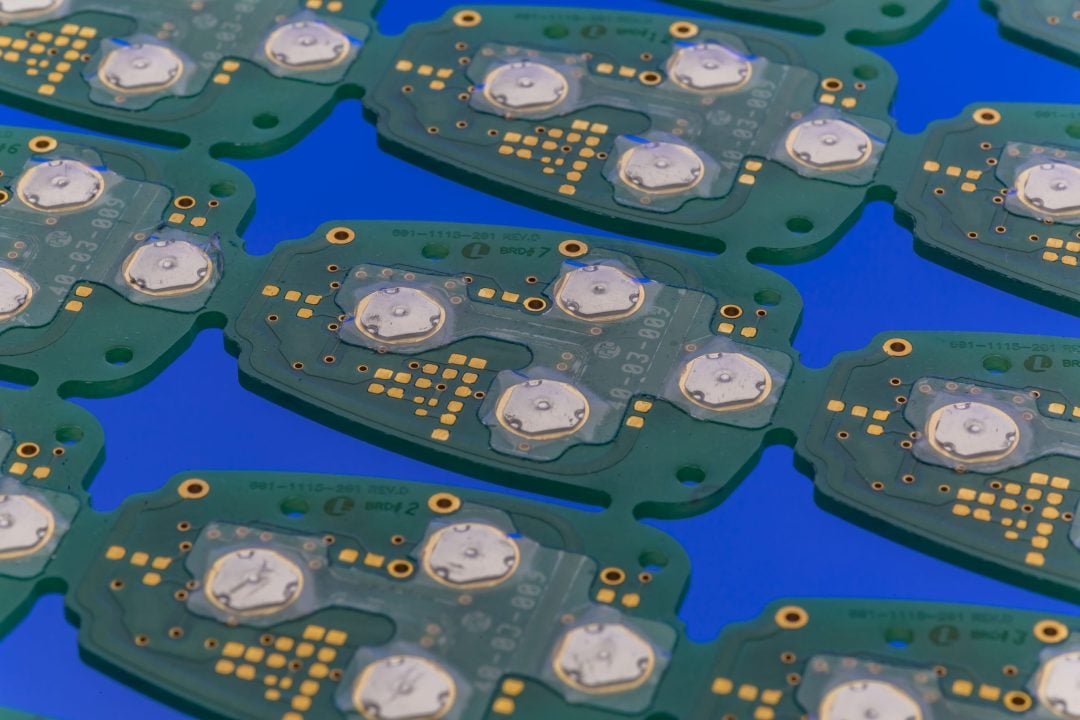

Q. Can the domes be soldered to a circuit board?

A. Yes, certain dome styles, such as the S-Series, can be soldered to a circuit. Two solderable tabs on S-Series, or SMD domes, allow the dome to be soldered directly to a printed circuit board or flex circuit without impacting performance or tactile feel. When the domes are pushed, the feet move outward. If this movement is restricted, it can negatively affect the tactile response of the domes and, in some cases, cause irreparable damage to the domes or break the solder joint. Therefore, Snaptron does not recommend soldering when not using solder domes.

Q. How is the S-Series different from your other domes?

A: The S-Series domes are a four-leg metal dome switch with two solderable tabs. Like standard tactile domes, the solder dome is a normally open momentary contact that provides a crisp tactile feel, letting the user know a button was pressed.

Q. How do I secure the metal domes to my PCB, membrane, or flex circuit?

A. Our metal domes are secured using pressure-sensitive adhesive tape or can be soldered down by hand or with an SMT machine in a solder reflow process, depending on the style of the dome. Several standard adhesive material options, as well as custom materials, are available. See our Peel-N-Place Arrays for more information on placing the domes with tape.

Q. Can your domes be assembled with standard pick and place equipment?

A. Yes, Snaptron offers tape and reel packaging for use with automated placement equipment. Please contact us for more information regarding placing domes with surface-mount technology (SMT) equipment.

Q. Do I need a special pick and place or tool head for the dome?

A. If using a standard vacuum nozzle-type tool head, ensure the tip has a rubber tip that can accommodate the round surface contours of the dome. For all other tools, please consult your pick and place manufacturer or tool head manufacturer.

Q. What soldering method should I use, and how much solder paste should I apply?

A. Our domes have been validated with lead-free and leaded solder pastes, although lead-free is recommended. We recommend using a 0.005″ thick stencil covering 40%-50% of the solder pad area. Always verify that the solder paste is applied in the correct area to avoid an inadequate solder joint or solder wicking.

Q. Can the solder dome be used in double-sided soldering procedures?

A. Yes. If placing the domes during the first soldering step, you may add adhesive material like Kapton (polyimide) after soldering to hold the domes in place during the reflow of the other side. This material may entirely cover the domes, but this is not required.

Q. What do trip force (Fmax), release force (Fmin), and the tactile ratio of a dome mean?

A. The actuation force, or trip force, is the amount of force that is necessary for the dome to “snap,” changing the dome from the open position to the closed position. Typical actuation forces range from 40 grams to 2,250 grams or higher, depending on the size. Snaptron measures actuation force in grams. The release force is the force the dome exerts on itself to return to its relaxed state. The combination of actuation and release force gives you the tactile ratio for a dome. The higher the tactile ratio, the “crisper” a dome feels when actuated. Snaptron U-Series domes are specifically designed with a high tactile ratio. A tactile ratio that is too high may affect the life of a dome in certain applications.

Note: Tactile ratio = (Fmax – Fmin) / Fmax x 100

Q. What does it mean to over-travel a metal dome?

A. Actuating the dome past its designed travel. For most domes, this is beyond the flat plane of the foot. Some domes are designed to over-travel; for example, M-Series domes are meant for this purpose.

Q. Is there a recommended actuator for depressing the domes?

A. While there are various sizes and shapes of actuators, we test the actuation force of our domes with a 0.050 diameter, flat-bottom plunger. See Test Procedures for more information on testing the domes. We recommend that your actuator size is no more than 25% of the dome size. Anything larger has the potential to damage the dome.

Q. Is venting required for optimal dome performance?

A. While venting is not absolutely necessary for every application, it is desirable in almost all applications. When the dome is depressed, the air is trapped underneath it. To avoid compressing the air under the dome when actuated, it is recommended that a vent channel be present. The venting of the dome can be achieved in several different ways. Some examples: a.) vent channel can go from dome to dome via a spacer layer b.) dome arrays can be top vented through the polyester material c.) vent channel can go through the board. Not properly venting the dome will result in a significant loss of tactile response.

Q. What is the purpose of a dimple in the center of a dome?

A. Various Snaptron domes have a dimple in the center. The typical depth of the dimple is 0.001” to 0.002” but may vary depending on the dome style. A dimple reinforces or improves the dome’s contact with the PCB.

If you haven’t found the answer to your question in the FAQ section, we are here to help. Feel free to reach out to us with your inquiry.